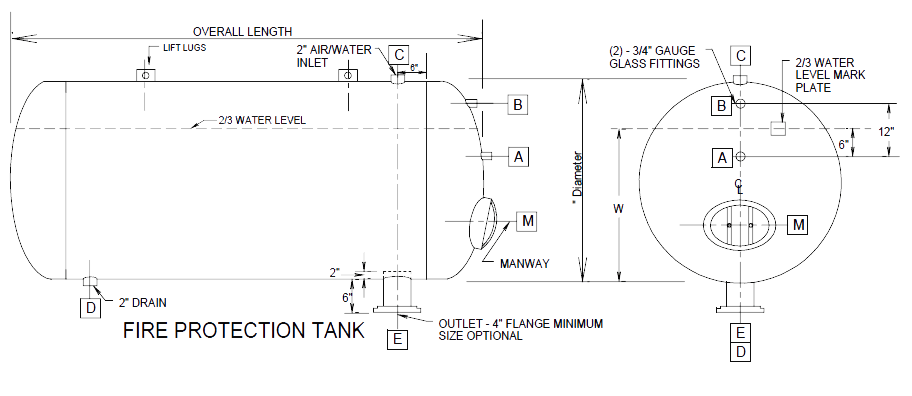

A pressure tank used as part of a private fire protection system.

Our fire protection tank is a pressure tank used for private fire protection systems. These tanks are constructed in accordance with the latest ASME code specifications, under Section VIII, Division 1 and meet the specifications as required by the latest edition of National Fire Protection Association pamphlet #22.

To determine the capacity for the tank in this system, we suggest you refer to the latest NFPA pamphlet #13, Standard for the Installation of Sprinkler Systems. In all cases, sizing must meet the requirements of the local or state governing authority having jurisdiction.

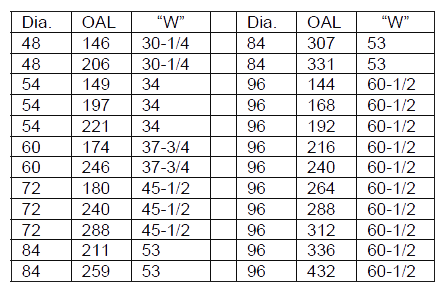

The outline drawing shown here was specifically designed to meet ASME and NFPA requirements. If the governing authority requires changes, Wendland can fabricate the custom-designed vessel to your requirements.

In addition to the standard hydrostatic test dictated by the ASME Code, we will test the tank to meet NFPA #22 requirements. NFPA requires the tank to be tested 24 hours at two-thirds capacity at normal working pressure and shall not lose more than one-half pound pressure in this period. We will furnish a signed certificate for the file of the governing authority certifying that the test has been successfully completed.

The NFPA requires the tanks be thoroughly cleaned by scraping, wire brushing, and wiping, and be painted inside and outside with at least two coats of an approved metal protective paint. As the interior is subjected to severe corrosion problems due to the standing water, we recommend the interior be painted with a coal tar lining or our standard Epoxoline.

Due to shipping, we recommend the exterior be prime painted at the factory and the finish coat is applied at the job site. We can finish out the exterior per your requirements if needed. Sandblasting is available at the factory when required. Refer to the lining section of our catalog for other available linings and further explanation.